7 Tips to Ensure AGV Commissioning Success

When it comes to delighting customers and ensuring the profitability of your AGV sale, quick and efficient commissioning is the goal.

BlueBotics’ team of expert engineers has installed, and helped customers to install, hundreds of AGVs and mobile robots at sites around the world. Below are our seven top tips for AGV commissioning success.

1. Plan, plan and plan again

The better you understand your customer’s site, and how their automated guided vehicles will operate within it, the smoother the AGV commissioning process will run.

“An ideal installation happens when the AGV buyer is well prepared, which helps you to be well prepared”

GUILLAUME ROSA-SERRANO – BlueBotics systems engineer

This means, of course, that your customer must have considered its desired AGV operation in-depth.

To ensure that is the case, here is a quick checklist of questions to ask prior to your arrival on-site:

Pre-installation checklist

- What separate tasks (missions) does your client want its AGVs to perform?

- Where will each vehicle go to pick, drop, charge and park?

- Has the client already proposed vehicle routes? If so, do these strike the right balance between minimizing the distance each AGV travels and on-site safety (in terms of other vehicles, foot traffic etc.)?

- Has the client properly measured their AGVs’ proposed paths? You might be surprised how many AGV buyers make a mistake with their measurements, which sometimes means paths are simply not wide enough.

- Which equipment and machinery do the AGVs need to interact with (e.g. automatic doors, machine interfaces, elevators etc.)?

- Is the client’s Wi-Fi network, if needed, in place, and is its signal strong enough across the site?

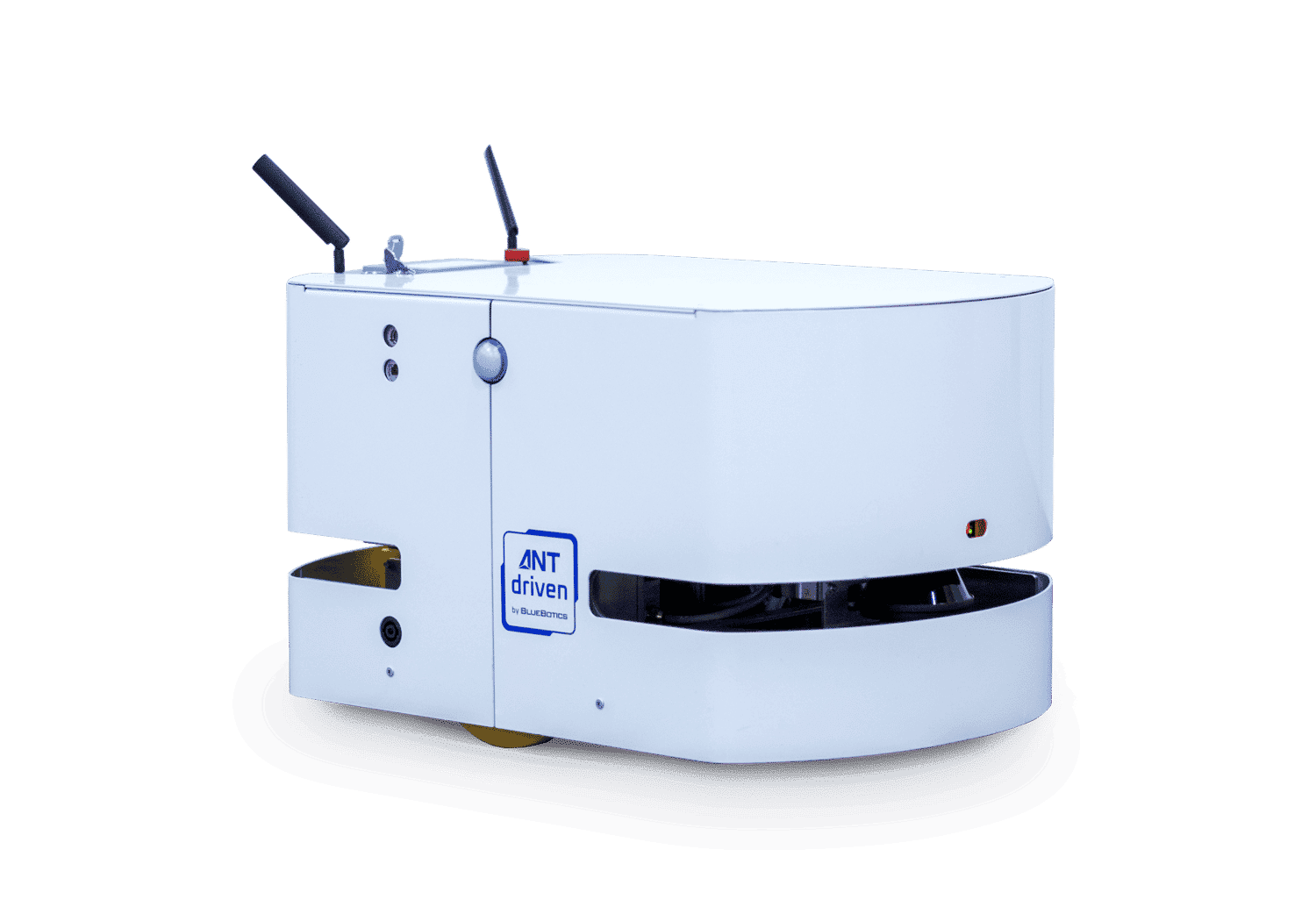

- What software does the client plan to use to manage its AGV missions? Are you expected to supply this (e.g. ANT server software can be used if the vehicles are driven by BlueBotics’ ANT lite+ technology), or will an API be needed to connect and manage AGV missions via the client’s existing WMS, MES or ERP system? Be sure to plan this out in detail and ensure your customer fully understands the time and work that might be involved with such an integration.

- Where can the AGVs be calibrated on-site without disturbing operations? This area should be flat, smooth, fairly large and not filled with clutter.

- Be sure to clearly communicate what work you expect the client to do ahead of time, no matter how small the task (e.g. installing power cables for battery chargers).

- Lastly, make sure your key client contacts will be on-site and available during commissioning. Without them, other colleagues might be afraid to take decisions, slowing the project down and causing frustration.

“An ideal installation happens when the AGV buyer is well prepared, which helps you to be well prepared,” says BlueBotics systems engineer Guillaume Rosa-Serrano. “If everything can be prepared well in advance – routes, actions, nodes – then your installation team will just need to concentrate on tuning the vehicle and mapping the site.”

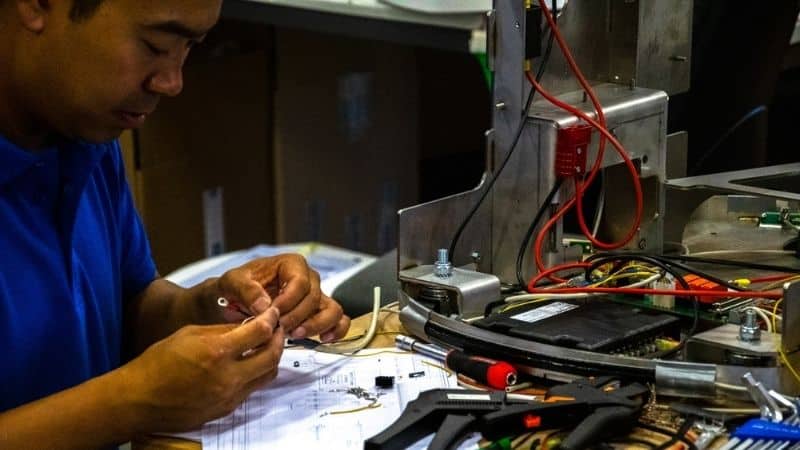

2. NEVER install an AGV that is not ready

According to BlueBotics’ VP of Development, Grégoire Terrien, probably the worst mistake a company can make is to try and install a vehicle that is not ready.

“If everything can be prepared well in advance – routes, actions, nodes – then your installation team will just need to concentrate on tuning the vehicle and mapping the site”

“Many companies – especially startup producers – feel the need to grow fast and therefore rush to install a vehicle that is not ready to be installed. This never goes well,” he explains. “It means effectively finishing your vehicle at the customer’s site, which gives a terrible impression and usually leads to bad vehicle performance.”

3. Pay close attention to environmental factors

This should be part of the planning process, but it is worth highlighting: do not underestimate the potential of small environmental factors to bring a commissioning process to a grinding halt.

System engineer Guillaume Rosa-Serrano provides an example: “The laser scanners used for localization on one company’s AGV were 2.7 meters above the ground. At one customer’s site the floor sloped down to the center in a soft V-shape, to make sure any water drained away. The AGV was supposed to see the walls of the room as references. The initial installation was done with empty pallets in place and everything worked fine. But, when real pallets were added, the AGV would always become lost because the full pallets were 2.60 meters high which, with the V-shaped floor, meant the AGV could not see any walls at all.”

Once the issue was detected, the team were able to quickly correct it – but this example demonstrates that the environment must be taken into account.

4. Have components ready

It is important to have access to your vehicle’s components during installation in order to avoid delays, says Terrien: “This is particularly important for drives – you might need to tune their parameters or replace them if not. You should also prepare safety components so you have these on hand, like redundant encoders.”

5. Simulate and test

Before deploying your client’s AGVs, always try to fully simulate the project you have created.

In the case of automated vehicles that run on BlueBotics’ ANT lite+ platform, simulations are carried out using ANT server software. This allows you to simulate not only basic missions such as single-vehicle picking and dropping, but even full fleet operations including traffic management.

The value of such a thorough check should not be underestimated. It is perfectly possible, for example, to solve all traffic issues fleet ahead of time – vastly reducing you and your client’s stress level when they finally click “GO”.

“Before deploying your client’s AGVs, be sure to fully simulate the project you have created.”

Camille Boymond of BlueBotics’ project management team (previously a systems engineer), describes a recent commissioning that went smoothly due to the simulations run beforehand: “Working together with our customer, a leading AGV producer, we simulated the end client’s project, which was an installation of five vehicles. Through this, we managed to solve all the traffic issues in advance. We even developed specific devices for the client that we were also able to test.”

The team had been assigned four days to get everything up and running, Boymond says. “We changed a few details on the vehicle to have the behavior the customer wanted, then we tested all the positions with all the vehicles to ensure high accuracy. In the end, we could already prove on day three that the project worked. That meant we had plenty of time to solve those unplanned issues that always pop up and we could leave the site with the client’s AGVs running in production exactly as expected.”

6. Ensure your client’s team are well trained

In addition to careful planning, your client’s own staff will also determine success of their AGV program.

Therefore, it pays to encourage your client to do the following:

- Minimize staff stress and resentment by communicating clearly and ahead of time about its AGV program. What will the vehicles be doing? How and where will they work? How will their staff need to interact with your products? Some customers find that ‘personalizing’ their AGVs – giving them visible names or adding faces or even just eyes) – can help to create a more harmonious relationship between your client’s humans and its mobile robots.

- Inform staff when and how the AGV commissioning process will take place. Your client won’t want its staff to be distracted by the process and, equally, you don’t want them to slow down the installation team’s work – so ask your client to keep staff fully informed in order to avoid surprises.

- Make sure the staff who will operate the AGVs are well suited to the job and train them well.

- Also, ensure more than one person receives this valuable education. If your client bestows all this knowledge on only one team member and they then leave the company, or get sick, the success of the entire AGV program will be put at risk – which could reduce your company’s future revenue.

In addition to fully training your client’s AGV operators, it is also a good idea to create – or help them to create – an operation manual. Your navigation technology partner, such as BlueBotics, can likely help with this.

7. Be patient & flexible

It is rare for the commissioning process to go 100% smoothly. While you can minimize the pain to a large extent, there will almost always be some hiccups.

One key to success is your relationship with your customer’s team. Be flexible, communicate well, and together adopt a problem-solving mindset,” explains system engineer Armand Lamouille. “A positive spirit of collaboration will make commissioning vehicles more likely to succeed and make the experience more pleasant overall.”

Lastly, and especially if you are new to commissioning AGVs, never underestimate the time required to fine-tune a project before launch. This will take longer than you imagine, but it will be time well spent because it will minimize your client’s future support requests.

Interested in learning more?

Get in touch to learn how quickly and cost-effectively vehicles driven by Autonomous Navigation Technology (ANT) can be commissioned.

Let's get Started

Take the first step to automating your vehicle.

Schedule a call with our expert team today.