5 AGV Development Mistakes to Avoid

Automated guided vehicle (AGV) development is a complicated business. While a robust, easy-to-use mobile robot could drive your vehicle business for years to come, producing such a cash cow is a process packed full of potential pitfalls.

So how can your business avoid these mistakes? How can you optimize your time and investment to get it right the first time? At BlueBotics we’ve helped producers develop AGVs for well over a decade, so we surveyed our team to identify the five most common mistakes in AGV development – and how to avoid them.

Mistake 1: Not knowing your application

Every industry has its own specific needs. An AGV destined for the automotive sector will likely need to perform different functions than a pure warehousing product or a hospital logistics robot.

For example, a lot of AGV development begins with the goal of sub-centimetre positioning accuracy, but in many cases – such as warehousing – accuracy of one centimetre is usually more than enough. In short, a generic vehicle that is designed to suit as many applications as possible may end up suiting none of them. It also stands a good chance of exploding your development budget.

Solution: Define success (but be prepared to change your mind)

Before speaking with an automation partner and starting prototyping, define what you want the end product to do – what you want it to achieve – and explore whether or not it actually needs to do this.

Run your vehicle plan past your suppliers, and if possible potential customers in your target industry, to see what features need to be added (or indeed eliminated). We sometimes see companies skip this step and move forwards with different (often more complicated) ideas about a vehicle’s required functionality than experts who know the target sector inside out. The result is almost always an unsuccessful product.

Mistake 2: Not hiring the right (number of) people

Starting an AGV development project without the right in-house expertise can lead to trouble and unforeseen expense. The roboticist on your team, for example, will ideally be an expert in mechatronics – skilled in mechanical, electronic, and computer engineering – to ensure they know how your vehicle works from end to end.

Not having the right level of detailed knowledge in-house can lead to costly mistakes (like installing a component meant for manual vehicles, which just won’t work in an AGV), lengthy delays (as your mechanical engineer scrambles to learn computer programming), and frustrating support calls with suppliers in future (because if your team doesn’t understand how your vehicle works, how can they fix it when it breaks?).

What would the potential cost of this brain drain be to your business? How does this compare to building a slightly larger team right now?

There is also the ‘bus factor’ to contend with. That is, the risk to your business of one of your employees disappearing from a project because they were hit by a bus. Or perhaps they leave the company, retire, or win the lottery. The result is the same: if you have only a single point of knowledge for your AGV project, this project risks grinding to a halt should that team member leave.

What would the potential cost of this brain drain be to your business? How does this compare to building a slightly larger team right now? Redundancy is not only valuable for components and systems.

Finally, also worth mentioning is the need for technical post-sales staff who can travel to customer sites to actually commission your AGVs. You might be surprised how many AGV developers forget to consider this. Will the staff you send to get your customers’ AGVs moving be the same people who developed them? If they are, this will of course slow down any new development work. Or will you build out a separate team to handle these revenue-generating installations?

Solution: Build a dream team

Try to hire a team with overlapping roles, not just a single person. It is true that hiring a second electrical engineer might be a hard sell to the CEO, but there are almost certainly people with complementary skills in the wider company who would be delighted to spend a few hours a week on a ‘robot project’. Invite them in (to create documentation if nothing else).

To avoid the bus problem, demand that today’s development team creates great documentation as they go. This way, new or replacement staff have more chance of succeeding in future. If your staff are not technical writers and show little interesting in becoming these, a series of screen recorded videos can do the job just fine.

Mistake 3: Focusing on the wrong costs

Like all R&D, AGV development can be expensive. But what we have learned from working with vehicle makers around the world is that cutting corners on hardware in the beginning often leads to increased costs in the long-term.

In a typical AGV project, hardware will represent almost all of the time and less than half the cost. So it makes sense to invest here.

To create an accurate vehicle, you need accurate measurements.

“Garbage in, garbage out”

To create an accurate vehicle, you need accurate measurements. Hardware therefore needs to be robust and high quality – especially components that measure variables such as the angle of steering, speed and traction. A saving of just $50 here may compromise the performance of an entire $100,000 vehicle, not to mention causing problems when installing and maintaining the AGV.

Solution: Choose top-of-the-line

When designing and prototyping your vehicle, think long-term and go for top-of-the-line components by default. Then, if you like, once your new AGV is working perfectly, cost the difference in price between top-shelf and standard hardware choices and decide which alternatives to test. You may find space for major savings – or the difference may be a lot less than you think.

Mistake 4: Automating the wrong vehicle

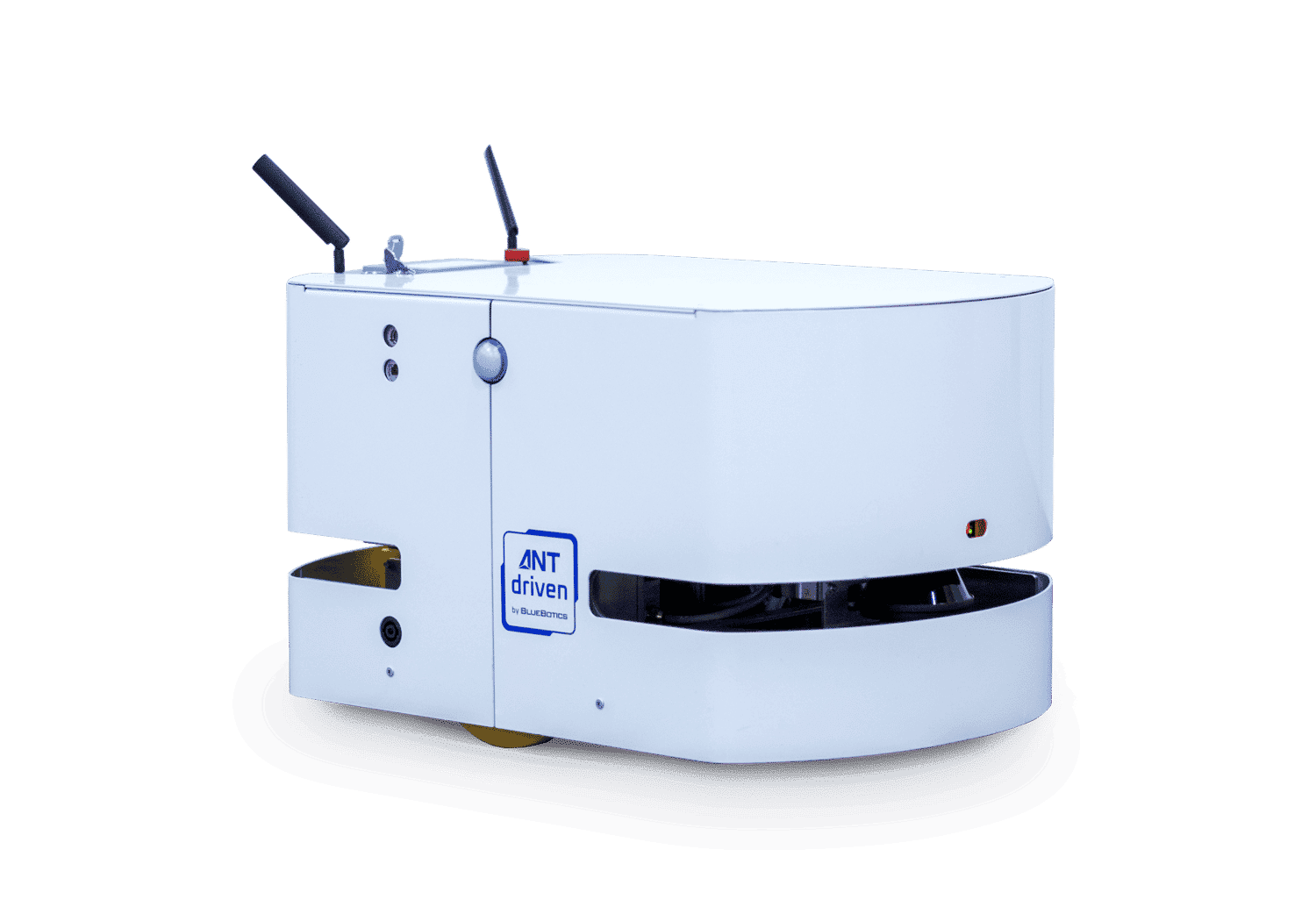

BlueBotics’ ANT navigation technology is flexible, accurate, and its integration inside your vehicle is supported by our expert team of robotics engineers. So, with tech like that, any vehicle can be automated, right?

In theory, yes. But in practice, the time and pain involved in automating some manual vehicles would be better spent automating another model or building an automated product from the ground up.

For example, automating a vehicle with fully mechanical steering means that a motor and encoder will need to be installed alongside the steering column – adding difficulty, expense, and a potential point of failure. Vehicles may also have mechanical throttles and brakes, which will need to be electrified before they can be automated. And manual-drive vehicles tend to feature built-in safety features that are designed to avoid human mistakes. These will need to be adapted to give an automated version the reactivity it needs.

Solution: Do your research

Discuss this topic carefully with your preferred automation supplier before getting started. Or, if you are planning to automate a third-party vehicle (such as an existing manual forklift), talk to that producer directly. A single phone call at this stage could help you avoid a world of development pain.

Mistake 5: Underestimating sales and marketing

AGV development is a significant financial investment. You’ll get the best ROI by ensuring as many people as possible hear about it.

A good idea is to expand your development team beyond R&D. Invite sales staff to your development meetings so they can input customer questions and feedback. Let your marketing manager take pictures and videos of your test runs. Offer beta customers a discount in exchange for permission to document their installations.

If no one knows about your new AGV, how can they buy it?

No in-house sales or marketing? You could hire an agency, or see if your suppliers or customers will help. Ask your suppliers to highlight your vehicle on their website and talk about it to their sales team – it contains components they manufactured after all!

After launch, ask happy customers to talk about how using your AGVs have made their businesses more efficient. Telling such success stories is win-win, as they speak not only to the excellent of your technology but also to your customers’ wisdom in facing the future and embracing new technology.

Solution: Make marketing a priority

The bottom line is your AGV development won’t be successful if you don’t sell the finished product. Make ‘sales and marketing’ a line item, and don’t launch without it.

Let’s get started

AGV development isn’t easy, but it’s worth it. At BlueBotics we have a large and growing team of engineers dedicated to helping companies succeed with their AGV projects. Explore our ANT navigation here or get in touch to set-up an obligation-free discovery call.

Let's get Started

Take the first step to automating your vehicle.

Schedule a call with our expert team today.