3 top tips for successful vehicle automation

In a new video, the CEO of BlueBotics, Dr. Nicola Tomatis, sits down to share his vehicle automation expertise.

He explains why vehicle manufacturers should consider automating their vehicles with autonomous navigation technology, and what to consider when starting down this path.

Watch now, or keep reading for an overview of the video:

Why should a vehicle producer consider automating their product portfolio?

Starts at: 0:12

Why automate? After all, industrial vehicles such as lift trucks and tow tractors are based on years or decades of R&D, and vehicle automation is a big investment.

“While most material handling is still manual, in reality today there is a clear trend towards automation,” says Tomatis.

In other words, to remain competitive in the long term: “Someone has to think about automating the vehicles for the future.” Shouldn’t that be your company, rather than your competitors?

In what applications are automated guided vehicles (AGVs) used?

Starts at: 0:34

Automatic guided vehicles were first used in automotive production, and pallet handling.

“Until twenty years ago, these were the only two applications,” says Tomatis. “In the last twenty years, a lot has been growing and changing. First of all, logistics took a lot of space, especially when combined with e-commerce. Even other applications outside automotive were gaining traction, and are still gaining traction – like production and electronics, but also plastic, metal, and food – which are gaining more and more importance in the AGV market.”

What types of AGV navigation technology exist?

Watch now

AGV navigation technology has been employed since the 1970s. First-generation vehicles followed a line on the floor, which could be an inductive wire, a painted line, or magnetic tape.

“A big revolution came in the 1990s when [laser] triangulation was born,” says Tomatis. “Triangulation is about using a laser on top [of the vehicle] to measure reflectors on the walls. The big difference between these two kinds of technologies is that the first one [line following] was very simple and robust, but very heavy to put in place and to maintain. Triangulation brought a simpler installation, but especially much easier maintenance.”

“Finally, let’s say between 2000 and 2010, natural feature navigation [also called natural navigation or SLAM navigation] came to the market. Natural feature relies more on the environment and made it much easier to install and maintain, and brought to the market much more flexibility in the use of AGVs,” he concludes.

What is natural feature navigation?

Starts at: 2:20

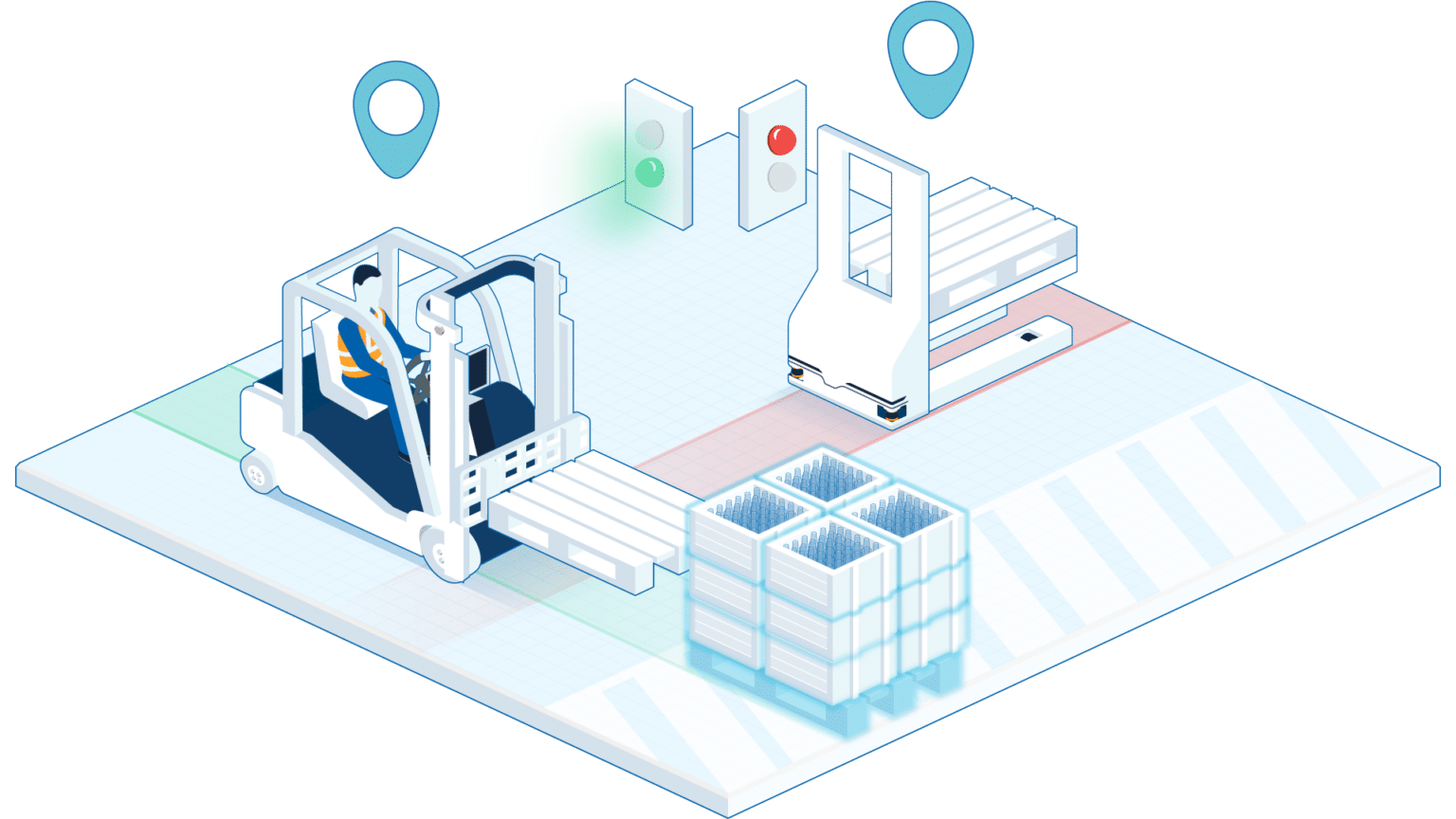

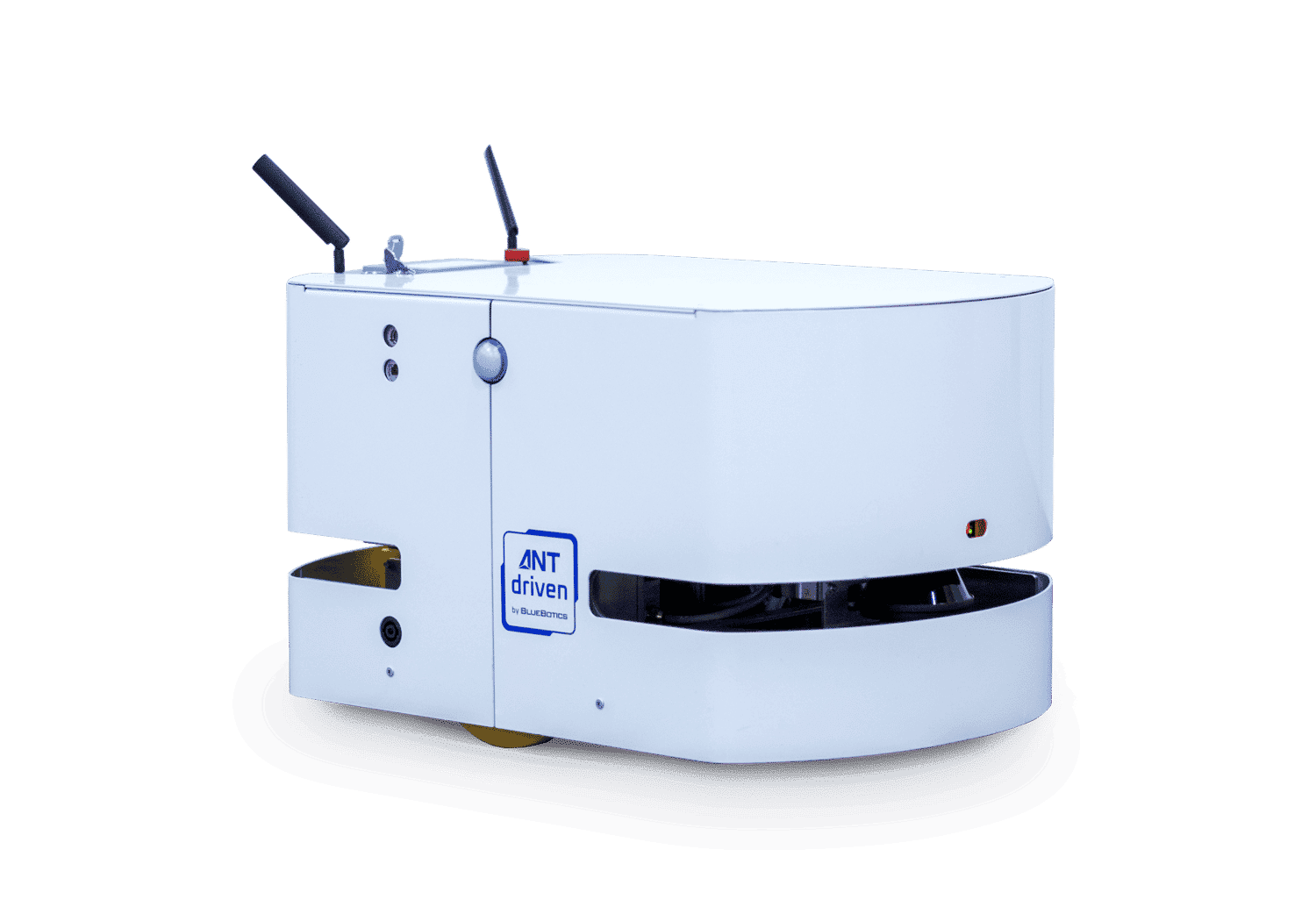

Tomatis gives a simple explanation of natural feature navigation: “It is about using structures or features in the environment in order to localize and know where the vehicle is.” Learn more about ANT navigation.

What types of application does natural feature navigation suit?

Starts at: 2:33

“This type of technology can be used for any kind of application,” says Tomatis. “Providing accuracy and robustness allows us to automate any kind of application.”

Natural feature navigation is used in many different applications, from vehicles picking and dropping pallets in warehouses and manufacturing plants, to driving commercial automated cleaning robots, hospital logistics AGVs, reception robots and much more.

How useful is obstacle avoidance in industrial settings?

Starts at: 2:56

“Obstacle avoidance is a big topic,” laughs Tomatis. “The topic is very broad because there are applications where avoiding obstacles makes sense, like if you have a cleaning machine that has to move everywhere, then you will find obstacles and it makes sense that you move around them. Or if you have a guide robot in an airport where it’s very crowded, there it makes sense.”

“Unfortunately, AMR suppliers try to sell this [obstacle avoidance] as the final solution – but it is not true. There are a lot of cases where it makes no sense.”

What are your 3 top tips for successful vehicle automation?

Starts at: 4:44

“The first tip is simple commissioning. In a very simplistic way, one says automation is 30% component cost and 70% integration cost. If a vehicle supplier wants to be competitive, you better reduce the cost of the 70%,” says Tomatis.

The final two tips are ensuring the technology is robust, and choosing a supplier who can stay with you for the entire project. “It’s a big investment, so make sure their support is good when you need it,” concludes Tomatis.

Let's get Started

Take the first step to automating your vehicle.

Schedule a call with our expert team today.