Manual, Automated or Hybrid Forklift? Deciphering the Difference and Decoding Forklift Certification Requirements

A hybrid forklift seems to offer the functionality of both a manual forklift and its fully automatic equivalent.

But what exactly is a hybrid forklift? How does it differ from a forked AGV (automated guided vehicle) or automated forklift – and why does it matter?

Whether you’re looking at adding automation to an existing manual forklift or creating a new AGF (automated guided forklift) from scratch, there are some important points to keep in mind to ensure your vehicle meets certification standards, and is safe to use.

In this article, we’ll cover:

- Definitions: the difference between manual forklifts, forked AGVs, automated and hybrid forklifts

- Forklift certifications and standards

- Developing hybrid or automated forklifts

- Hybrid forklifts: automating while keeping EN 1175 certification

- How we can help

Quick Definitions: Manual vs Automated vs Hybrid Forklifts

As we’ll see in this article, there are a lot of different variations on this essential piece of equipment. Let’s start with some quick definitions.

- A manual forklift is an industrial vehicle used to move pallets. Manual forklifts are driven by a worker, and are powered, so are distinct from a human-powered pallet jack. Manual forklifts are also called lift trucks, fork trucks, or forklift trucks.

- Forked AGVs are vehicles which have been created from the ground up as fully automated vehicles designed to move pallets. While they can be shifted manually from one place to another (often with a joystick), this is not a typical part of a workflow, and they do not have space for a human driver. Rather than being driven, automated forklifts follow a series of pre-programmed instructions (or respond to cues or signals) to move around a site and carry out actions such as picking, moving, and dropping pallets.

- An automated forklift is a manual forklift which has been altered to navigate autonomously. It functions in the same way as a forked AGV, and although it may still have a seat and steering wheel, it cannot typically be used as a manual forklift. Automated forklifts are generally less expensive than forked AGVs, because they are produces in higher volume; however, they can be difficult to customize for specific applications.

Both automated forklifts and forked AGVs are also referred to as automatic/automated guided forklifts (AGFs), driverless forklifts, robot/robotic lift trucks, or automated lift trucks. - Hybrid forklifts are vehicles which can both navigate autonomously, and be driven manually when required. Typically, these vehicles are not designed as hybrids from the ground up, but are manual vehicles which have been automated.

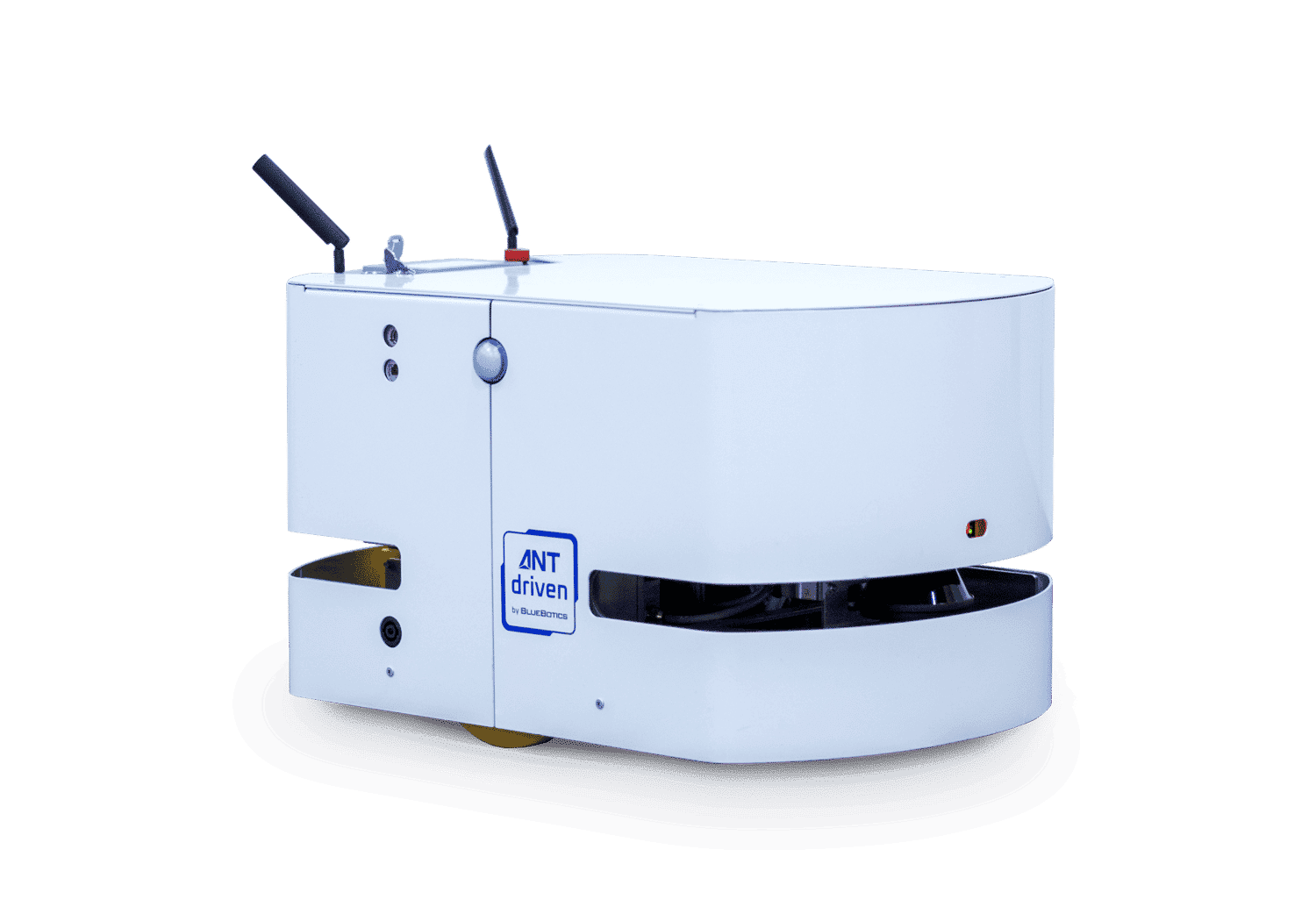

Looking for a forklift, but don’t want to automate your own? Check out ANTdriven.com to find hundreds over a hundred automated vehicles.

Forklift Certifications and Standards

We’ve defined hybrid forklifts, automated forklifts and forked AGVs – but from the shop floor, it may seem like these definitions don’t matter. After all, they’re all industrial vehicles which can move pallets autonomously.

But to vehicle makers and integrators, the distinctions are vital as they affect how a vehicle is certified.

Briefly,

- Manual forklifts must be certified with EN 1175.

- Automated vehicles must be certified with ISO 3691-4 (in Europe) or ANSI B56.5 (in the US) – this is true whether a vehicle is a forked AGV or automated forklift, or any other automated guided vehicle (AGV).

- Hybrid automated forklifts must both retain their EN 1175 manual forklift certification and additionally be certified with ISO 3691-4/ANSI B56.5.

Therefore, when a vehicle maker or integrator automates a manual forklift (whether to create a hybrid vehicle or a fully automatic machine), they must go through either the ISO 3691-4 (in Europe) or ANSI B56.5 (in the US) certification.

Developing Hybrid or Automated Forklifts

No one wants to create an unsafe vehicle. Ensuring the certification is up-to-date is a key part of developing safe hybrid or automated forklifts.

As we said above, a commercially available forklift must be certified with EN 1175. However, changing the vehicle’s components or software invalidates this certification.

This doesn’t mean certification is impossible. Automated vehicles must be certified with either ISO 3691-4 (in Europe) or ANSI B56.5 (in the US). However, keep in mind that your vehicle will not be EN 1175 certified anymore, unless you explicitly redo the certification.

Hybrid forklifts: Automating While Retaining EN 1175 Certification

In reality, it is possible to keep EN 1175 forklift certification while automating a manual vehicle. To do so, it is necessary to automate the vehicle without touching anything which affects manual operation. This requires some clever thinking, but is one way to create a hybrid forklift without needing to recertify.

If your goal is to create a hybrid vehicle which retains the EN 1175 certified manual setup, you need to discuss your plans with the manual forklift supplier. The forklift supplier can provide two ways to create a hybrid vehicle: with hardware or software.

The forklift supplier can add additional hardware, such as a specialized port, which allows switching between the manual controls and the automatic commands without affecting the manual operation in any other way. This may be your preference if you require the vehicle to literally switch between manual and automatic modes.

Alternatively, the vehicle might be controlled with software to allow switching from manual drive to automatic. This is typically integrated into the vehicle master control (VMC).

Either solution must be provided by the forklift supplier, who will ensure they are EN 1175 certified for their machines.

How We Can Help

Creating an automated vehicle of any sort is a challenge. That’s why it’s important to partner with a trusted supplier. At BlueBotics, our expert team has helped OEMs all over the world to create forked AGVs, automated forklifts, and hybrid vehicles.

Let’s look at the last two cases:

- When creating a hybrid vehicle, our team work with the vehicle maker and driver suppliers.

- Upgrading a manual forklift to an automatic forklift can be handled (almost) entirely by the BlueBotics team. We offer standard packages, with transparent pricing, and even train your team to work with the technology in the future.

In both cases, you will be responsible for the mechanical and electrical integration of the automation components, such as the safety PLC, sensors, and lights. However, our team can support this work if needed.

Let’s Talk

Interested in creating an automated vehicle, or just want some more information?

Get in touch for a free, no-obligation call to discuss your business’ unique needs.

Let's get Started

Take the first step to automating your vehicle.

Schedule a call with our expert team today.